WELCOME CONTACT WITH US THROUGH WHATSAPP: +86 180 0549 3293

What Is The Difference Between Cheap And Expensive Sintered Stone Slabs?

There are cheap and expensive sintered stone slabs on the market. Are expensive ones necessarily good? Are cheap ones fake? What is the difference between cheap and expensive sintered stone slabs?

Expert 1 Said:

Cheap sintered stone slabs are probably faked by large tiles. Real sintered stone slabs are pressed by a press with a capacity of over 10,000 tons, so they are very dense, resistant to oil stains, high temperatures, wear, and scratches, and are much different from real tiles.

Moreover, real sintered stone slabs are relatively thin, even 3mm, so the thickness is also a way to distinguish them.

Expert 2 Said:

The difference in production technology is the use of different machines. Expensive sintered stone slabs will use presses of more than 10,000 tons, with a pressure exceeding 15,000 tons. The sintered stone slabs produced have a high density and smooth surface and are free of impurities. The cheap ones use presses with much lower pressure, and the slabs have low hardness, high water absorption, and are easy to break.

Expensive sintered stone slabs are scratch-resistant, with a Mohs hardness of more than 6 degrees. They can withstand scratches and attempts to scratch, and will not crack or be scratched directly with a knife. Bacteria will not breed, and stains can be wiped off directly with a towel without penetrating the stone. It is fireproof and high temperature resistant, will not deform when exposed to high temperatures, will not have a bad odor, and will not leave marks when burned.

If you are laying sintered stone slabs over a large area, it is recommended to consider brands as the main focus, integrity and quality are guaranteed.

Expert 3 Said:

Now sintered stone is very popular in the market, and many brands are competing for this cake. There are so many sintered stone slab brands. How to distinguish the quality of sintered stone slabs?

Trick 1:

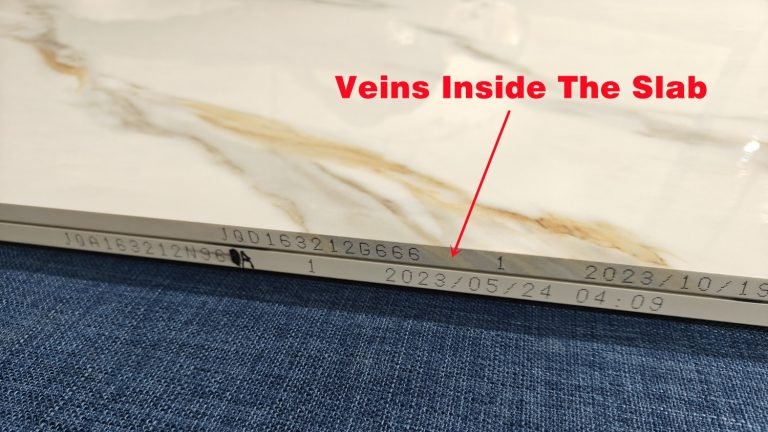

High-quality sintered stone slabs have a strong texture and distinct layers. It is a visual feast and an enjoyment for the eyes.

Trick 2:

The patterns of inferior sintered stone slabs are stiff, not up to grade, and feel inferior; secondly, look at the details, stand 20cm to 30cm away from the slab, and observe. The sintered stone slab is delicate and rich, refreshing and chic; the inferior sintered stone slab is blurred, chaotic, and confused.

Trick 3:

Look at the blank. High-quality sintered stone slabs generally have a high whiteness, while inferior sintered stone slabs have a low whiteness and impurities. If the blank is gray and yellow, then congratulations, you may have bought a ceramic slab instead of an authentic sintered stone slab.

Trick 4:

The splicing interface of the finished sintered stone slab has cracks and yellowing. It is not that the slab is bad, but that inferior glue is used. Good sintered stone slab furniture products also need high-quality auxiliary materials such as special glue to assist.

Expert 4 Said:

1. Processing Details

Details make success or failure, and good brands also win with details. Cheap sintered stone slabs are not as good as expensive ones in terms of edges and corners or surface colors. The cost of fine processing is high, and it cannot be processed at a low price, and it is also easy to break. The risk level is also high. Once you are not careful, it is easy to crack, causing the entire board to crack.

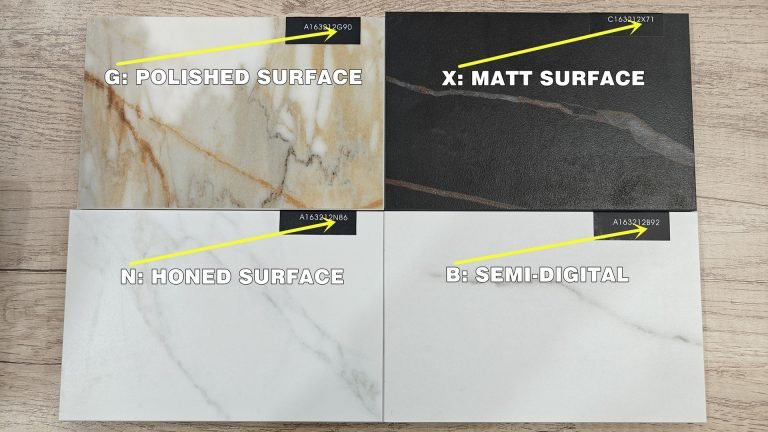

2. Different Textures

Domestic first-line brands and imported brands spend a lot of money to design patterns that meet the public’s aesthetic taste. The sintered stone slabs they made pay special attention to aesthetics, especially the color texture, and style, which are all based on the aesthetic taste of young people. The surface can be made into a delicate velvet surface, which can only be made by foreign factories at present.

3. The Tonnage Of Production Machines Is Different.

The production machines determine whether the sintered stone slabs are prone to edge collapse or cracking during long-term use, especially large slabs. The difference can be seen. Heavy presses and good pressing processes can make sintered stone slabs last longer.

Expert 5 Said:

The main difference between cheap stone slabs and expensive ones is the difference in the raw materials and production processes. Expensive slabs use high-quality raw materials and have advanced production processes. The slabs produced are of better quality.

Expert 6 Said:

Brand premium, this thing can be judged by craftsmanship, just compare the production process. Expensive does not necessarily mean good, after all, this thing is a new material, the profit margin is large, and cheap might be because the manufacturer gives up more profit to gain market share.

Expert 7 Said:

“Expensive Does Not Mean Good“

Expert 8 Said:

The main difference is in the process.

Expensive sintered stone slabs have good production technology, using high-quality raw materials and presses of more than tens of thousands of tons, with a pressure of more than 15,000 tons. The sintered stone slabs produced have a smooth surface, and with the naked eye, no impurities can be seen at all.

Cheap sintered stone slabs use inferior raw materials and a relatively small press pressure. The slabs produced have low hardness and high water absorption. They are easy to break, and various defects can be seen with the naked eye. Many cheap sintered stone slabs on the market are impersonated by large tiles, so when purchasing, try to choose big brands.

Expert 9 Said:

Expensive sintered stone slabs are made of imported high-quality natural stones such as granite, marble, and quartzite. The production process is more advanced, and the finished products have better performance in all aspects. My family bought the sintered stone slabs at a famous brand store. The surface is smooth, the texture is clear, and it looks more upscale.

Expert 10 Said:

The main difference between cheap and expensive sintered stone slabs is the raw materials and craftsmanship.

1. Raw Materials

First of all, the raw materials of sintered stone slabs are natural stones, such as natural stone powder, feldspar, and other natural raw materials. Good sintered stone slabs are processed with natural raw materials, so they are not prone to deformation, cracking, and other quality problems after long-term use.

The raw materials of cheap sintered stone slabs are often substitute materials or low-quality waste materials from secondary processing. The slabs made of these raw materials are prone to cracking, deformation, fading, and other problems in the later stage, which is annoying.

2. Craftsmanship

In terms of craftsmanship, the requirements for the craftsmanship of sintered stone slabs are very high, so the expensive sintered stone slabs are pressed by a press of more than 10,000 tons, combined with advanced production technology, and then fired at a high temperature of more than 1200℃. There are no defects in the finished product, and it can withstand the cutting, drilling, grinding, and other processing processes during decoration.

Cheap sintered stone slabs are all processed by simple manual processing, and the equipment is not advanced, so the quality is unstable and there are many defects.

So, if you want to buy sintered stone slabs, you can take a look at the well-known first-line brands such as Linx. Although they are more expensive than ordinary stone slabs, they are more cost-effective and the quality is 100% guaranteed.

IN THE END

As A New Stone Product, SINTERED STONE Has Become A Strong Competitor To Marble, Granite And Quartz Stone. Sintered Stone Is A Stone You Can Not Ignore. If You Also Want to Develop A Brand Of Your Own, Come To Us, We Are The Right Choice.

CONTACT US AT

Email: hero@linxsintered.com

WhatsApp: +86 180 0549 3293

USEFUL LINKS

YOUTUBE CHANNEL: LINX SURFACES CHINA

WIKI: Sintered Stone Linx “Wikipedia”

Difference Between Low-Quality And High-Quality Sintered Stone