WELCOME CONTACT WITH US THROUGH WHATSAPP: +86 180 0549 3293

Sintered Stone Linx “Wikipedia”

Here We Introduce The Very Popular Stone In Stone Business, a Strong Competitor To Traditional Stone Like Marble, Granite, Quartz Stone Etc. Sintered Stone “Wikipedia” By Linx.

A new type of porcelain material made from natural raw materials fired with a special process.

SINTERED STONE, is made of natural raw materials through a special process, pressed with the help of a press of more than 10,000 tons (more than 15,000 tons), combined with advanced production technology, and processed at a high temperature of more than 1200°C A new type of oversized porcelain material that is fired and can withstand cutting, drilling, grinding and other processing processes.

SINTERED STONE SLABS are mainly used in the field of home and kitchen. As a new species in the home furnishing field, slate home furnishings have the characteristics of large specifications, strong moldability, diverse colors, high-temperature resistance, wear and scratch resistance, anti-penetration, acid and alkali resistance, zero formaldehyde, environmental protection, and health compared with other home products.

INTRODUCTION OF SINTERED STONE

SINTERED STONE, which means “sintered stone”.

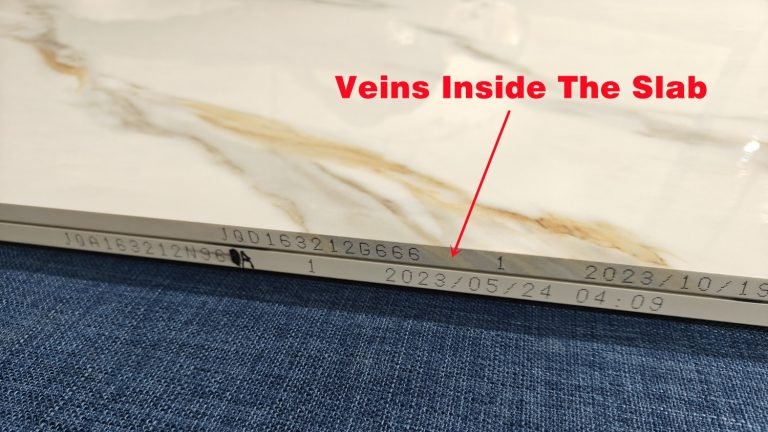

It is harder than igneous rocks such as granite. Sintered stone is made of natural stone powder, feldspar, and other natural raw materials through special technology.

With the help of presses of more than 36,000 tons and NDD technology. It is fired at high temperatures above 1200℃.

A new type of oversized stone material that can withstand various high-intensity processing processes.

The sintered stone slabs are available in 1000×3000mm, 1200×2700mm, 1800×900mm, 2400×1200mm, 2600×800mm, 2600×1200mm, 760×2550mm, 2700×1600mm, 3200×1600mm, 3600×1600mm, and other specifications. Thicknesses include 3mm and 6mm. , 9mm, 11mm, 12mm, 15mm, 20mm.

EXCELLENT PERFORMANCE OF SINTERED STONE SLABS

Compared with traditional ceramic slab products, the production requirements of SINTERED STONE SLABS are very high.

The very important thing is ceramic large slabs ≠ sintered stone slabs. Companies that can produce large slabs may not necessarily be able to produce sintered stone slabs. Compare with ceramic large slabs, sintered stone slabs can be drilled, polished, and easier to cut, and are suitable for various shapes. Although the shape of ceramic slabs is similar to that of sintered stone slabs, there are certain differences in material properties and functions.

As a new material, SINTERED STONE SLAB has eight major advantages compared to other traditional materials:

(1) Safety And Health: It can be in direct contact with food, purely natural materials, 100% recyclable, non-toxic, and non-radiative, and fully consider the needs of human sustainable development, healthy and environmentally friendly.

(2) Fire Resistance And High-Temperature Resistance: It will not deform when in direct contact with high-temperature objects. A1-level fire-resistant rock slabs will not produce any physical changes (shrinkage, cracking, discoloration) when exposed to an open flame of 2000°C, nor will they emit any gas or odor.

(3) Anti-Fouling: The water permeability rate of one ten-thousandth is a new indicator in the field of artificial building materials. While stains cannot penetrate, it does not give space for bacteria to breed.

(4) Scratch Resistance: Mohs hardness exceeds 6 degrees, able to resist scratches and attempts to scratch.

(5) Corrosion Resistance: Resistant to various chemical substances, including solutions, disinfectants, etc.

(6) Easy To Clean: Just wipe it with a wet towel to clean it, no special maintenance requirements, simple and fast clean.

(7) All-round Application: Breaking the application boundaries and marching across boundaries from decorative materials to applied materials. Moreover, the design, processing, and application are more diversified and extensive to meet high-standard application needs.

(8) Flexible Customization: The textures of sintered stone slabs are rich and diverse, good for various needs. Attached: Performance comparison table of different decorative materials (based on test results of different materials)

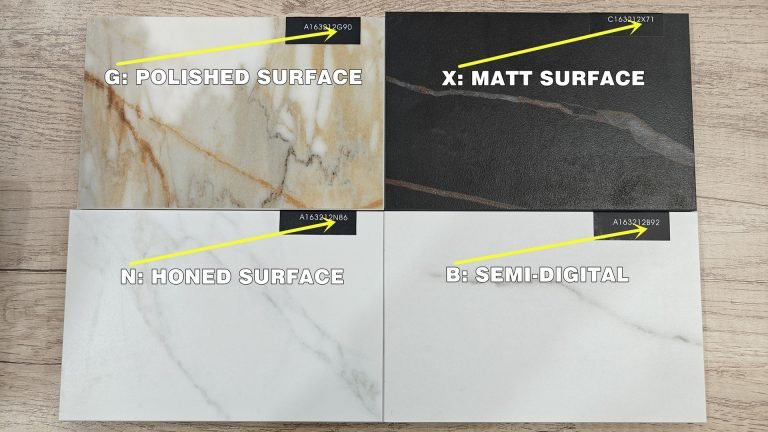

PROCESSING OF SINTERED STONE SLABS

Compared with traditional decorative materials, SINTERED STONE SLABS have larger specifications and require higher cutting and processing quality. More professional processing services are needed to achieve the processing and application of sintered stone slabs.

IN THE END

As A New Stone Products, SINTERED STONE Has Become A Strong Competitor To Marble, Granite And Quartz Stone. Sintered Stone Will Be A Stone You Can Not Ignore. If You Also Want to Develop A Brand Of Your Own, Come To Us, We Are The Right Choice.

CONTACT US AT

Email: hero@linxsintered.com

WhatsApp: +86 180 0549 3293

USEFUL LINKS

YOUTUBE CHANNEL: LINX SURFACES CHINA

WIKI: Sintered Stone Linx “Wikipedia”