WELCOME CONTACT WITH US THROUGH WHATSAPP: +86 180 0549 3293

What Are The Advantages And Disadvantages Of Sintered Stone Slabs?

Sintered stone, has become one of the most popular stone over granite, marble and quartz stone etc, has the advantages of large, light, thin, hard, etc.

First of all, we need to understand its concept and what sintered stone slab is.

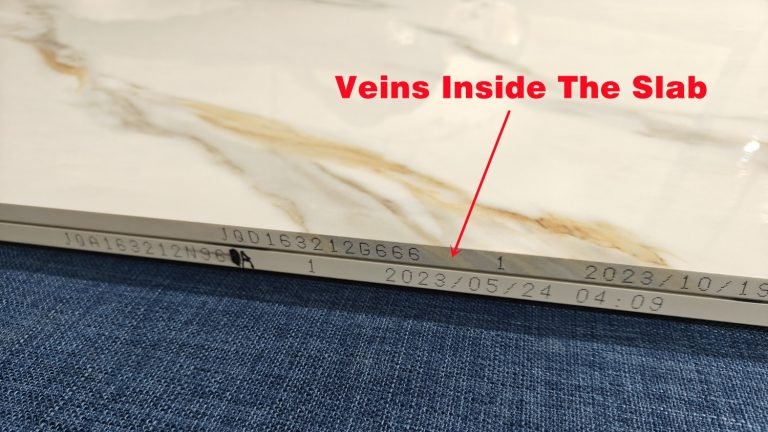

Sintered stone, which can be said to be an upgraded ceramic sheet. It is made of natural materials, pressed by advanced technology, and then fired at a high temperature of more than 1,200.

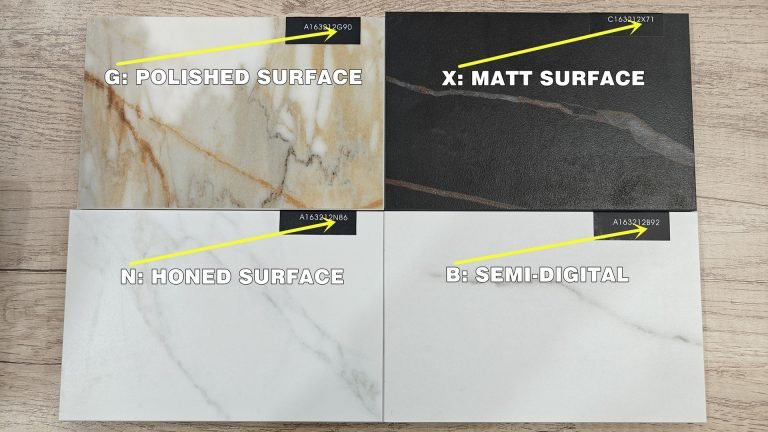

Sintered stone has rich designs and textures. It is not only versatile, practical, but also highly decorative. It can replace materials such as stone, ordinary ceramic tiles, ordinary ceramic sheets, and wallpaper, and can instantly improve the quality of your home space.

Secondly, let’s look at its material properties.

Advantages Of Sintered Stone

1. Big, Light and Thin

Due to the particularity of the slate technology, it can be presented in ultra-large specifications with extremely thin thickness, that is, 3600x1200x3mm, which increases the use area of the material in the space and reduces the visual division of the material, thereby maintaining the integrity of the space.

2. Wear-resistant And Corrosion-resistant

Compared with ordinary ceramic tiles and marble, Sintered stone slabs are very wear-resistant and corrosion-resistant. Scratches or oil stains will not have much impact on the slabs. They are practical and durable.

3. Fireproof And High Temperature Resistant

Because the sintered stone itself is fired at ultra-high temperature, it also has good fireproof and high-temperature resistance.

It can be used flexibly in the kitchen, and some boiling and heating pots can be placed directly on the slate countertop without turning black or cracking.

4. Anti-penetration And Easy To Clean

The sintered stone material itself has a dense structure, and dirt will not easily penetrate into the material, leaving traces that are difficult to deal with. On the contrary, it is very convenient to clean. If some soup, sauce, or oil stains are stained, just wipe it gently with a wet paper towel and it will be gone.

5. Rich Texture

In addition to the practicality of the material, it is also very decorative. There are a variety of textures and patterns to choose from, such as stone grain series, wood grain series, solid color series and volcanic rock series, which can be used in different scenes and styles.

6. Widely Used Materials

Tables

The table made of sintered stone is light and simple, with a metal bracket, lively and beautiful, and can add different visual highlights to the living room.

Background Wall

Conventional sintered stone slab sizes are 3200X1600mm, 1800X900mm, 3000X1000mm, 2400X1200mm, 2600X800mm, etc. The sizes are all relatively large.

Therefore, it is very appropriate to use sintered stone slabs to pave the background wall. It can ensure the visual integrity of the wall and inject a sense of high-end into the space.

Kitchen Countertops

In fact, the most commonly used place for sintered stone is on kitchen countertops. Using sintered stone slabs with different textures to create kitchen countertops can meet the kitchen’s needs for wear-resistant, high-temperature-resistant, and easy-to-clean materials, giving cooks a better cooking experience.

Disadvantages Of Sintered Stone

Finally, no matter how good the material is, it has two sides. Although sintered stone has many superior properties, it also has some shortcomings and precautions:

1. High process requirements

Being large, light and thin is its advantage, but also its disadvantage. During processing or transportation, it can be easily broken if you are not careful, and burrs will appear if the pressure is not enough, so the process requirements are extremely high.

2. Not suitable for facade modeling

Although sintered stone slabs are rich in texture, they have limitations in modeling. For example, the hardness is too high and cannot be used to create lines and three-dimensional curved surfaces.

3. Leave gaps between the boards

In order to avoid the phenomenon of thermal expansion and contraction, during the installation process of the sintered stone slabs, attention should be paid to leaving a gap of 0.5~1mm between the sintered stone slabs.

IN THE END

As A New Stone Products, SINTERED STONE Has Become A Strong Competitor To Marble, Granite And Quartz Stone. Sintered Stone Will Be A Stone You Can Not Ignore. If You Also Want Develop A Brand Of Your Own, Come To Us, We Are The Right Choice.

CONTACT US AT

Email: hero@linxsintered.com

WhatsApp: +86 180 0549 3293

USEFULL LINKS

YOUTUBE CHENNEL: LINX SURFACES CHINA

WIKI: Sintered Stone Linx “Wikipedia”

SINTERED STONE FOR BEND: Ultra-Thin 3mm Sintered Stone Slab