WELCOME CONTACT WITH US THROUGH WHATSAPP: +86 180 0549 3293

Ultra-Thin 3mm Sintered Stone Slab

Ultra-thin sintered stone slab refers to the specification of thickness 3mm, jumbo size such 3600X1200mm. It is crafted from a blend of natural stone and inorganic clay, undergoing a specialized process. This involves utilizing cutting-edge vacuum extrusion equipment and a fully automated, closed-loop computer system to control temperature, culminating in firing at 1200 degrees Celsius. A new type of stone sheet.

Features Of Ultra-Thin Sintered Stone Slab

Ultra-thin sintered stone slab is made of natural stone and inorganic clay through a special process, using the most advanced vacuum extrusion molding equipment and a fully automatic closed computer temperature-controlled roller kiln and fired at 1200 degrees. It is currently the thinnest (only 3mm). The largest existing porcelain decorative sintered stone slab in the world (3600×1200mm), weighing only 7KG per square meter.

1. Flexural Strength And Impact Resistance

Although the thickness of the ultra-thin sintered stone slab is only 3mm, its flexural strength and impact resistance have not been weakened at all. At the same time, it also saves resources and energy consumption, reduces the pressure on the environment during the manufacturing process. Sometime we can combine it with other Material for a variety of purposes to make products with special material properties. It also suitable in extreme environments such as acid and alkali resistant laboratory countertops, hospital antibacterial walls and worktops.

2. Adapt To Various Scenarios

Because the subversive large size of ultra-thin sintered stone slab is 3600×1200mm, and its essence is a porcelain decorative building board, as an exterior wall, a single board can span the floor, giving it a grand and natural appearance. The large-area exterior wall paving has natural colors and soothing patterns, giving the building a fashionable and grand style. When paired with unique and novel architectural designs, it gives people a strong visual impact. For example, bright glass combined with light gray ultra-thin slate gives a strong visual impact. But the noisy and chaotic atmosphere of the past has change. An atmosphere that is inclusive of everything is revealed in the calmness.

3. Impressive Flexibility

At the same time, it also leads a splendid new concept that pays attention to the collision of heritage and creativity to burst out sparks. Although the 3mm ultra-thin sintered stone slab only weighs 7KG per square meter, it can be used to make large ventilated and insulated curtain walls, which greatly reduces the load-bearing load of the building and is environmentally friendly and energy-saving;

We can also them to renovate and renovate the walls of old buildings. It is convenient and quick to directly cover the original walls by hanging them dry. What is even more amazing is that it have toughness that ordinary ceramics do not have, and can be bent into a radius at room temperature. It is a 5-meter arc, exuding the infinite charm of arc curves.

Ultra-Thin Sintered Stone Slab Compare With Ceramics

The world’s largest single ultra-thin sintered stone slab specification 3600X1200mm(4.32 square meters), greatly reducing construction time and costs. The product specifications are complete, We can flexibly cut it into any size to meet the needs of different customers.

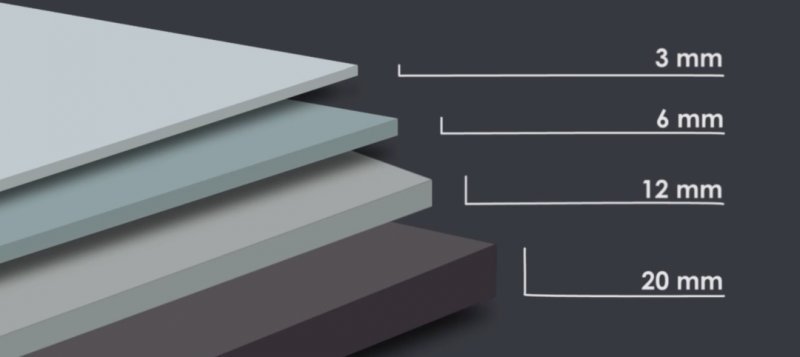

The ultra-thin sintered stone slab is only 3mm thick, it’s energy-saving and environmentally friendly, lighter in weight, less logistics costs, and effectively reduces the load on the building itself. The thickness can also be flexibly stacked to configured to facilitate application in different environments and base layers.

Traditional ceramic products are fundamentally different from ultra-thin sintered stone slabs in terms of raw material and production process. Traditional ceramic use dry pressing equipment for producing, the flatness of large-sized products produced by pressing will have problems. The ultra-thin sintered stone slabs use vacuum extrusion equipment and fully automatic CNC production lines originating in Italy. The 3600X1200X3MM ultra-thin sintered stone slabs are formed in one time. The computer numerically controlled kiln temperature 10,000 square meters and 4 colors at least, which is incomparable for most of the manufacturers.

Due to its own characteristics of ultra-thin, ultra-large, ultra-light and ultra-tough, ultra-thin sintered stone slab has completely broken through human understanding of ceramic materials in the traditional sense. Compared with the so-called “ceramic thin plates” and “thin ceramic tiles” , the definition of ultra-thin sintered stone slab is closer to a high-tech decorative panel with high strength, high durability, and completely sintered from natural inorganic components.

Selling Points Of Ultra-Thin Sintered Stone Slabs

- New Stone, Not just ceramic tiles, but also a new type of decorative stone panel.

- Thinner, only 1/3 thickness of traditional ceramic tiles,

- Lighter, even less than 1/3 thickness of traditional ceramic tiles. The average weight of traditional ceramic tiles is 23-27kgs/m2, while the average weight of ultra-thin sintered stone slabs is only 7kgs/m2, making it easy to transport and install.

- Flexibility, The unique size of 3mm thickness and 1.2×3.6 meters, its softness can be bent to form an arc. Naturally formed architectural arc-shaped structure paving. The paving effect is very impressive, with few seams, good overall effect and easy to clean.

- Ultra-High Hardness: You can use iron nails or knife edges to scratch the surface of the sintered stone slab, it won’t leave any traces.

- Anti-Fire, It is high temperature resistant and does not contain organic materials. Its fireproof and high temperature resistant performance has passed the A1 level fire protection standard. In the event of a fire, the product itself will not produce smoke or emit toxic substances. It is perfect for office/home/furniture surfaces. Not only can it be shaped at will, it is also praised for its fire safety.

- Extremely Low Water Absorption: Calcined at 1200 degrees high temperature, the ultra-thin sintered stone has ultra-high density and a water absorption rate of only 2/10,000, making it impossible for any stains to remain on the surface of the surface. Just wipe the stains lightly with water and it will be as clean as new.

- Light Transmittance: The diffuse light penetration rate can reach up to 2.5%. The world’s unique ceramic-like material that can transmit light provides more space for other interior designs such as building curtain walls, stairs, and background walls.

- Easy to cut. It can be cut into any size according to the required size using ordinary glass and ceramic cutters or computer-controlled automatic cutting machines. The base thickness of 3mm makes drilling easier. Because the sintered stone slab itself is extremely dense, the cutting and drilling process causes very little damage.

- Facilitate house renovation. The 3mm ultra-thin sintered stone slabs can be laid directly on old ceramic tiles without dismantling them. Save time and money.

- Strict production control, The production process is fully automated and computer monitored, and color number control is extremely strict. Up to 4 color numbers per 10,000 square meters.

- For indoor and outdoor wall Cover, especially on exterior walls, its light and stable safety performance reduces the weight load of building exterior walls. Compared with other types of exterior wall products, it does not deform, does not fade, has high hardness, is moisture-proof, has no radiation, and is durable.

- Light-weight and ultra-thin, it can keep a large space between the ventilated curtain wall and the wall, which facilitates the installation of insulation materials and the construction of a natural ventilation system (chimney effect). In addition, no need for renovation of the exterior walls of old buildings.

- Maintenance Free And Anti-Fade, Super self-cleaning ability, sunlight resistance and resistance to external wear and tear. so a sintered stone building exterior wall will be always clean as new.

- Nature And Total Healthy, It is an all-natural product that itself can be simply crushed and recycled.

IN THE END

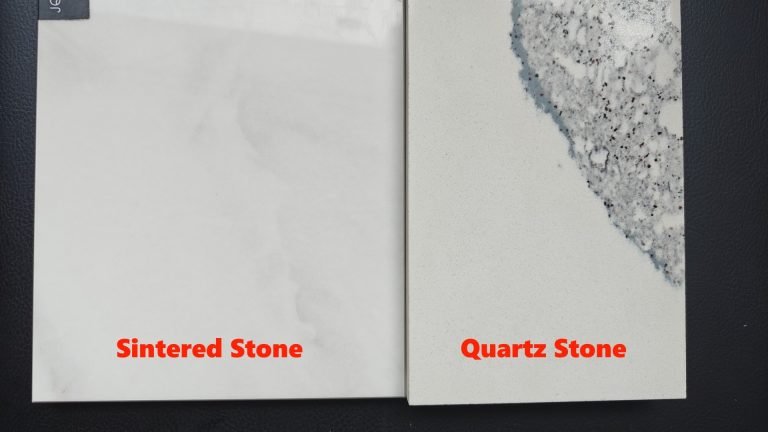

As A New Stone Products, SINTERED STONE Has Become A Strong Competitor To Marble, Granite And Quartz Stone. Sintered Stone Will Be A Stone You Can Not Ignore. If You Also Want Develop A Brand Of Your Own, Come To Us, We Are The Right Choice.

CONTACT US AT

Email: hero@linxsintered.com

WhatsApp: +86 180 0549 3293

USEFULL LINKS

YOUTUBE CHENNEL: LINX SURFACES CHINA

WIKI: Sintered Stone Linx “Wikipedia”